Rod Bar Core Magnetic Choke Coils Power Inductor for Filtering Applications

TR series

Share

Describe

Inquiry Us

Rod Bar Core Magnetic Choke Coils Power Inductor for Filtering Applications

Rod Bar Core Magnetic Choke Coils, or power inductors, are vital components in various electrical and electronic applications. Here are their features, specifications, and typical applications:

Features:

- High Inductance Values: They provide high inductance, which helps in energy storage and filtering applications.

- Rod Bar Core Design: The cylindrical shape enhances magnetic coupling and reduces losses.

- Low DC Resistance: This feature minimizes heat generation and maximizes efficiency.

- High Saturation Current: They can handle high current levels before saturating, making them suitable for power applications.

- Compact Size: Their design allows for space-efficient integration into circuits.

- Low EMI Emissions: Designed to minimize electromagnetic interference, ensuring compliance with regulations and reducing noise in systems.

- Temperature Stability: Usually constructed to operate effectively across a range of temperatures.

- Versatile Termination Options: Available with various terminal types (e.g., surface mount, through-hole) for different design needs.

Specifications:

- Inductance Range: Typically from microhenries (µH) to millihenries (mH).

- Current Rating: Varies based on specific designs but can typically handle several amps.

- DC Resistance (DCR): Low resistance values, often in the milliohm range, depending on the specific inductor.

- Saturation Current: Defined maximum current before the inductance significantly drops (varies widely based on core material and design).

- Operating Temperature: Usually specified over a range, e.g., -40°C to 125°C.

- Core Material: Magnetic materials such as ferrite or powdered iron are often used.

Applications:

- DC-DC Converters: Used as energy storage elements in step-up (boost) or step-down (buck) converters.

- Filtering Applications: Employed in power supplies to filter out noise and stabilize voltage.

- Power Management Circuits: Integral in managing power distribution in battery-operated devices.

- Audio Equipment: Used in inductive coupling applications to improve sound quality.

- Automotive Electronics: Found in power supply circuits for ECUs, lighting, and other electronic systems.

- Telecommunications: Used for signal filtering and power regulation in communication devices.

- Renewable Energy Systems: Applied in inverters and converters in solar and wind energy systems.

-

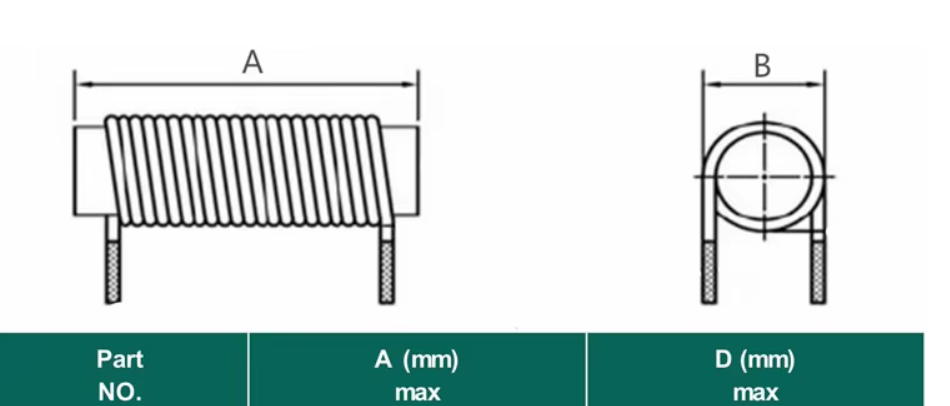

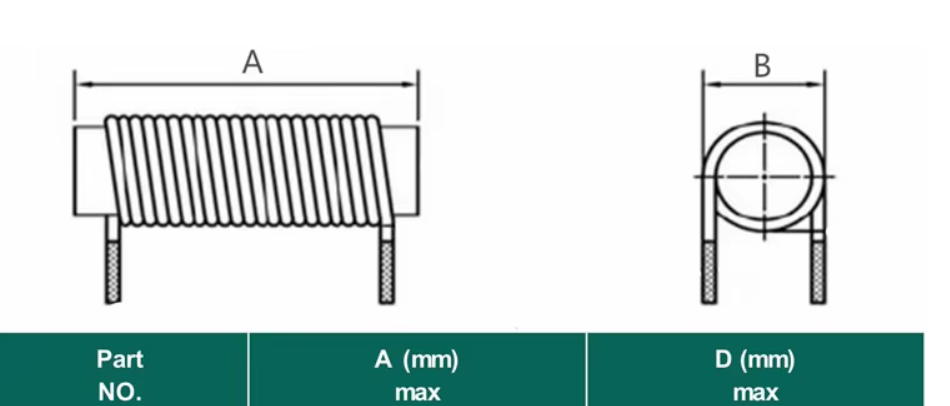

Part No A mm (Max) B mm (Max ) TR0310 10.5 5 TR0312 12.5 5 TR0315 15.5 5 TR0320 20.5 5 TR0325 25.5 5 TR0410 10.5 6.5 TR0412 12.5 6.5 TR0415 15.5 6.5 TR0420 20.5 6.5 TR0425 25.5 6.5 TR0430 30.5 6.5 TR0510 10.5 8 TR0515 15.5 8 TR0520 20.5 8 TR0525 25.5 8 TR0530 30.5 8 TR0612 12.5 9 TR0615 15.5 9 TR0620 20.5 9 TR0625 25.5 9 TR0630 30.5 9 TR0635 35.5 9 TR0815 15.5 11 TR0820 20.5 11 TR0830 30.5 11 TR1020 20.5 13 TR1025 25.5 13 TR1030 30.5 13 TR1035 35.5 13 TR1040 40.5 13 Part Number Inductance

uHIDC (mA)

MaxDCR

MAX(Ω)Wire Turn( ref) TR0310-1R8K 1.8 1900 0.026 0.55 11.5 TR0310-2R2k 2.2 1570 0.028 0.5 13.5 TR0310-2R7K 2.7 1570 0.03 0.5 15.5 TR0310-3R3k 3.3 1270 0.035 0.45 17.5 TR0310-3R9K 3.9 1000 0.05 0.4 18.5 TR0310-4R7K 4.7 760 0.07 0.35 19.5 TR0415-4R7K 4.7 2260 0.024 0.6 17.5 TR0415-5R6K 5.6 1900 0.03 0.55 18.5 TR0415-6R8K 6.8 1570 0.04 0.5 21.5 TR0415-8R2K 8.2 1270 0.06 0.45 24.5 TR0415-100K 10 1000 0.08 0.4 22.5 TR0520-100K 10 2.65 0.04 0.65 23.5 TR0520-120K 12 2.26 0.044 0.6 27.5 TR0520-150K 15 1.9 0.06 0.55 27.5 TR0520-180K 18 1.57 0.08 0.5 32.5 TR0520-220K 22 1.27 0.1 0.45 32.5 TR0520-270K 27 1 0.15 0.4 36.5 TR0630-4R7K 4.7 16.08 0.005 1.6 12.5 TR0630-5R6k 5.6 16.08 0.005 1.6 14.5 TR0630-6R8K 6.8 10.61 0.008 1.3 15.5 TR0630-8R2K 8.2 9.04 0.009 1.2 16.5 TR0630-100K 10 9.04 0.01 1.2 19.5 TR0630-120k 12 6.28 0.018 1 20.5 TR0630-150K 15 5.08 0.023 0.9 23.5 TR0630-180K 18 4.02 0.03 0.8 24.5 TR0630-220K 22 3.07 0.045 0.7 27.5 TR0630-270K 27 3.07 0.05 0.7 31.5 TR0630-330K 33 2.65 0.06 0.65 35.5 TR0630-390K 39 2.26 0.08 0.6 40.5 TR0630-470K 47 1.9 0.11 0.55 44.5 TR0630-560K 56 1.57 0.14 0.5 46.5

Welcome to our website. If you have any requests or suggestions,please feel free to email us at lydia@czystech.com or use the following enquiry form. Please allow us to provide you with the best service.