RXLG 400W Aluminum housed non-inductive brake resistors For inverters

RXLG

RXLG 400W Aluminum housed non-inductive brake resistors For inverters

Dynamic braking resistor for inverters

Industrial brake resistors

Introducing the RXLG 400W Aluminum Housed Brake Resistor, a premium solution designed specifically for inverters, ensuring optimal performance and reliability in dynamic braking applications.

Unique Selling Points

High Power Capacity: With a robust power rating of 400W, this resistor is engineered to handle demanding applications, providing superior braking performance compared to competitors that may falter under heavy loads.

Aluminum Housing: The durable aluminum housing not only enhances thermal management but also ensures longevity and resistance to environmental factors. This feature sets it apart from plastic or less robust alternatives, making it ideal for both indoor and outdoor installations.

Wide Resistance Range: Offering a resistance range of 1Ω to 10,000Ω, the RXLG 400W provides versatility for various applications. This adaptability makes it a preferred choice for engineers looking for tailored solutions.

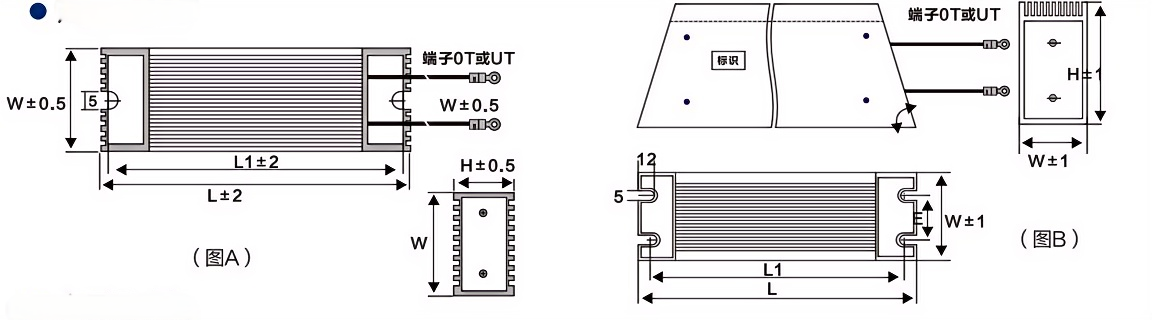

| Rated power | Overall | Dimension(mm | Adaptive variable Power(KW) |

Matching Electricity old value(R |

||||||

| L | L1 | W | H | E | lead wire | Line length | ||||

| 50-60 | FigureA | 115 | 98 | 40 | 20 | 350 | 0.4-0.75 | 750 | ||

| 80 | 140 | 123 | 40 | 20 | 1 | 350 | ||||

| 100 | 165 | 148 | 40 | 20 | 1 | 350 | 1.5 | 390 | ||

| 120 | 190 | 173 | 40 | 20 | 1 | 350 | ||||

| 150 | 215 | 173 | 40 | 20 | 1 | 350 | ||||

| 200 | 165 | 147 | 60 | 30 | 1.5 | 350 | ||||

| 300 | 215 | 197 | 60 | 30 | 1.5 | 350 | 2.2-3.7 | 150 | ||

| 400 | 285 | 247 | 60 | 30 | 1.5 | 350 | ||||

| 500 | 335 | 317 | 60 | 30 | 1.5 | 350 | 5.5 | 100 | ||

| 800 | 400 | 382 | 60 | 30 | 2 | 350 | 7.5 | 75 | ||

| 800 | FigureB | 400 | 382 | 61 | 59 | 40.5 | 2.5 | 350 | ||

| 1000 | 400 | 384 | 50 | 107 | 30 | 2.5 | 350 | 11 | 40-50 | |

| 1200 | 450 | 434 | 50 | 107 | 30 | 2.5 | 350 | |||

| 1500 | 485 | 470 | 50 | 107 | 30 | 4 | 350 | 15 | 40 | |

| 2000 | 550 | 532 | 50 | 107 | 30 | 4 | 350 | 15-18.5 | 20-40 | |

| 2500 | 550 | 532 | 50 | 107 | 30 | 4 | 350 | |||

| 3000 | 550 | 532 | 50 | 107 | 30 | 4 | 350 | |||

| 4000 | 700 | 686 | 50 | 107 | 30 | 4 | 350 | 18.5-22 | 20-32 | |

Electronical Parameters

|

Characteristics

|

Standards

|

Test methods

|

|

Resistance and Resistance tolerance

|

Resistance tolerance±5% (J)

|

/

|

|

Temperature coefficient

|

±300ppm

|

Test the resistance value at normal temperature and normal temperature added 100℃,calculate per℃ resistance value change rate .

|

|

Power rating load

|

△R/R≦± (1%+0.05Ω)

temperature 350℃ Max.

|

the power rating is applied to the resistor kept horizontally for 30 min.

|

|

Short-time overload

|

△R/R≦± (2%+0.05Ω)

|

At 10× rated voltage for 5 seconds.

|

|

Insulation resistance

|

≥1000MΩ

|

DC500V

|

|

Dielectric withstanding voltage

|

Without damage by flash-over, fire. or breakdown, etc.

|

≥AC2500V,60(sec.)

|

|

Vibration

|

no evidence of mechanical damage

|

Frequency:10~55Hz,Amplitude:1.5mm

|

|

Terminal strength

|

no evidence of mechanical damage

|

(Pull):150N , 30± 5 seconds

|

|

Resistor strength

|

no evidence of mechanical damage

|

250N,30± 5seconds

|

|

Heat resistance

|

△R/R≦± (1%+0.05Ω)

|

Immerge into 375±10℃ tin stove for 2~3 seconds.

|

|

Thermal shock

|

△R/R≦± (2%+0.05Ω)

|

Overload rated voltage or Max.working voltage (get the lower) for 1000 hours (1.5 hours on and half-hour off ) at the 40±2℃ and

90~95% relative humidity. |

|

Power rating load

|

△R/R≦± (5%+0.05Ω)

|

Overload rated voltage or Max.working voltage (get the lower) for 1000 hours (1.5 hours on and half-hour off ) at the 40±2℃ and

90~95% relative humidity. |

|

Load life in heat

|

△R/R≦± (5%+0.05Ω)

|

Overload rated voltage or Max.working voltage (get the lower ) for 1000 hours (1.5 hours on and half-hour off) at the 70±2℃.

|